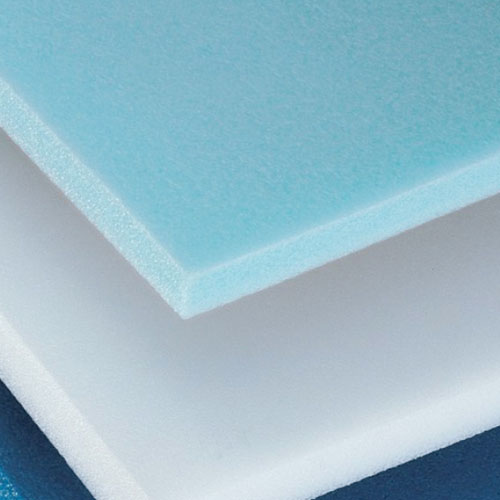

Polyethylene

foam

Whether providing comfort and support for sporting goods, to packaging fragile electronics, polyethylene foam offers the durable, lightweight, closed-cell characteristics you need. Because it is resilient and flexible, it can take repeated shocks and combines vibration dampening and insulation properties with high resistance to chemicals and moisture to protect against damage.

Its high load bearing characteristics help reduce packaging costs by using thinner and smaller amounts of foam. Polyethylene’s tear and compressive strength allows manufacturers to reuse it several times, reducing their costs and helping the environment. polyethylene is easily fabricated into a variety of shapes and sizes with inexpensive steel rule dies and custom cut patterns.

Polyethlyene is a closed cell foam available in densities from .9-9 pounds per cubic foot, allowing for package designs for a variety of product weights and sizes. Cross-linked polyethylene adds the ability to protect class “A” surfaces, and is often used in the packaging of medical devices and equipment.

Applications

- Cushion Packaging

- Display Packaging

- Low Pressure Gaskets

- Floatation Devices

- Insulation Cushion Devices for Construction, Medical, Recreational and Manufacturing Applications

- Material Handling in and between plants

- Anti-Static Grades

Characteristics

- Closed Cell

- Non-dusting

- Very Lightweight

- Excellent shock absorption and vibration dampening properties

- Nonabrasive

- Easy to fabricate

- Impervious to mildew, mold, rot and bacteria

- Superb strength a tear resistance

- Flexibility

- Resistant to water, chemicals solvents and grease

- Odorless

- Very cost-effective

- CFC free

- Excellent themal insulation properties

- Excellent buoyancy

OUR SERVICES

Custom Fabrication

Clark Foam Products makes it our business to develop and produce exceptional flexible foam products to meet the exact requirements for each and every customer. We have the expertise, experience, and technology to satisfy your most challenging foam component, packaging and product challenges.

Design Services

Clark Foam Products will combine cutting-edge engineering and foam conversion processes with a dedication to quality and complete customer satisfaction. We will work with you to design your custom component, packaging or product, select the proper materials and have your solution manufactured and shipped.

Image to DXF

Clark Foam’s patented .dxf imaging is portable imaging technology allows for on-site rapid imaging of tools and components. In a simple three-step process, our Portable Imaging Technology will create and catalog as many as three files a minute, creating a completed spec of tools or components, this is achieved by converting jpeg images into .dfx files.

Full list of industries served

Our offices

CHICAGO PLANT

655 Remington Boulevard

Bolingbrook, IL 60440

LOUISVILLE PLANT

7100 Trade Port Drive

Louisville, KY 40258